Understanding The Cost Of Engine Head Rectification: A Comprehensive Guide

Apr 01 2025

Engine head rectification is a critical process for maintaining the performance and longevity of your vehicle's engine. Whether you're dealing with a damaged engine head or simply want to ensure optimal performance, understanding the cost involved is essential. This article will delve into the intricacies of engine head rectification, providing you with valuable insights and actionable information to make informed decisions.

As one of the most complex components of a vehicle's engine, the cylinder head requires precise maintenance and repair when issues arise. Rectifying an engine head is not just about replacing parts—it involves diagnosing problems, machining components, and ensuring proper assembly. The process can vary significantly in cost depending on several factors, including the vehicle's make and model, the extent of damage, and the chosen repair facility.

In this comprehensive guide, we will explore everything you need to know about engine head rectification, including the average costs, key factors influencing pricing, and tips for finding reliable repair services. By the end, you'll have a clearer understanding of the financial implications and how to approach this essential maintenance task effectively.

Read also:Da Bears Caleb Williams The Rising Star Of College Football

Table of Contents

- Introduction to Engine Head Rectification

- Overview of Rectification Costs

- Factors Affecting the Price

Understanding the Repair Process

- Diagnosis and Inspection

- Machining and Resurfacing

- Parts Replacement

- Labor Costs

Preventing Future Issues

- Maintenance Tips

- Frequently Asked Questions

- Conclusion

Introduction to Engine Head Rectification

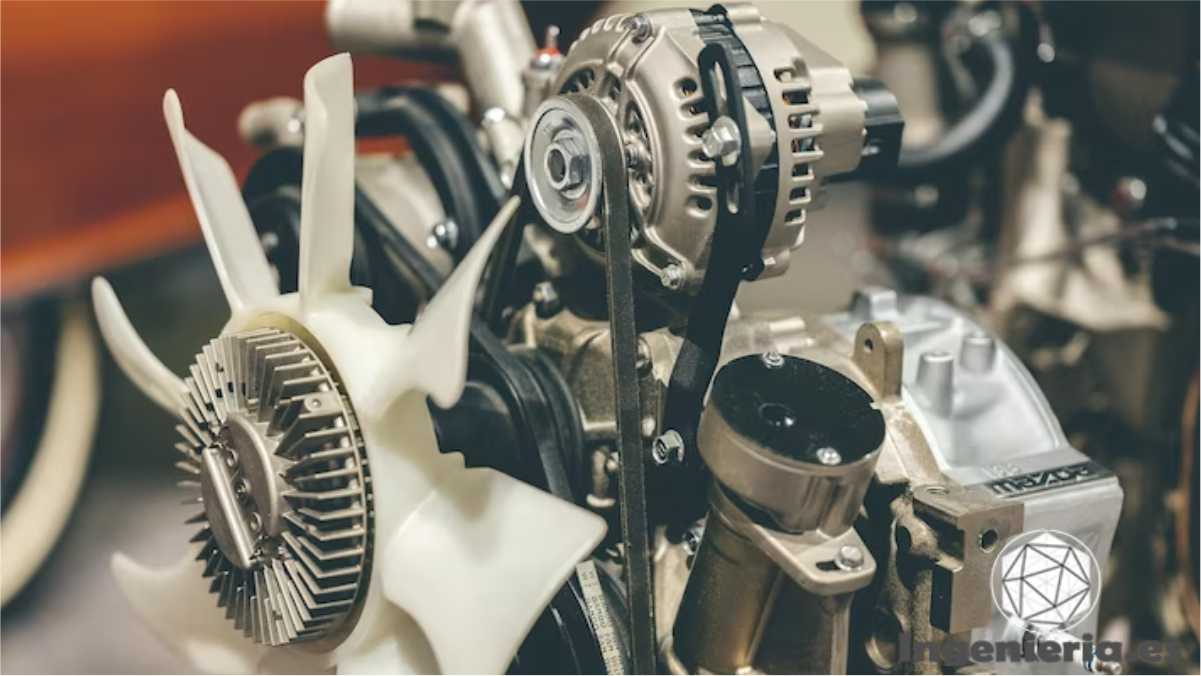

The engine head, also known as the cylinder head, is a crucial component that plays a vital role in the combustion process. Over time, wear and tear, overheating, or mechanical stress can lead to damage, necessitating rectification. Rectification involves repairing or replacing damaged components to restore the engine head's functionality and performance.

Engine head rectification is more than just a repair task; it’s an investment in your vehicle's longevity. By addressing issues early, you can prevent more severe damage and costly repairs down the line. Understanding the costs associated with this process is key to budgeting effectively and ensuring your vehicle remains in top condition.

Overview of Rectification Costs

When it comes to rectifying an engine head, the cost can vary widely depending on several factors. On average, you can expect to pay anywhere from $500 to $2,500 for the entire process. This includes both parts and labor costs. However, the exact price will depend on the specific issues with your engine head and the type of vehicle you own.

It's important to note that luxury or high-performance vehicles may incur higher costs due to the complexity of their engine designs and the need for specialized parts. Additionally, the location of the repair shop and its reputation can influence pricing.

Factors Affecting the Price

Several factors contribute to the overall cost of engine head rectification:

- Vehicle Type: Different vehicles have varying engine designs, which can affect the complexity of the repair process.

- Extent of Damage: Minor issues like warping may require less extensive repairs compared to severe damage such as cracks or leaks.

- Parts Quality: High-quality parts generally come at a higher cost but offer better durability and performance.

- Labor Costs: Skilled technicians and specialized tools can increase labor costs, but they ensure a more reliable repair.

Understanding these factors can help you better anticipate the total cost of your rectification project.

Read also:Bulking Burrito Recipe The Ultimate Guide To Building Muscle With Flavor

Understanding the Repair Process

Diagnosis and Inspection

The first step in any engine head rectification is a thorough diagnosis. This involves inspecting the engine head for signs of damage, such as warping, cracks, or leaks. A qualified technician will use specialized tools to assess the condition of the head and determine the necessary repairs.

During this stage, the technician may perform a compression test or leak-down test to identify any performance issues. These tests help pinpoint specific areas of concern and guide the repair process.

Machining and Resurfacing

If the engine head is warped or damaged, machining and resurfacing may be required. This process involves using precision machinery to restore the head's flatness and ensure proper sealing. Resurfacing is essential for maintaining the integrity of the head gasket and preventing future issues.

The cost of machining can vary depending on the severity of the damage and the equipment used. However, it is a crucial step in the rectification process and should not be overlooked.

Parts Replacement

In some cases, parts replacement may be necessary. Common components that may need replacing include the head gasket, valves, and seals. Using high-quality replacement parts is essential for ensuring the longevity of the repair.

While premium parts may come at a higher cost, they offer better performance and durability, ultimately saving you money in the long run.

Labor Costs

Labor costs can vary significantly depending on the complexity of the repair and the technician's experience. A skilled technician with access to specialized tools and equipment may charge more for their services, but this often translates to a higher-quality repair.

When budgeting for labor costs, it's important to consider the time required for the repair process. Complex repairs may take several days, leading to higher labor charges.

Preventing Future Issues

Maintenance Tips

To prevent future issues with your engine head, regular maintenance is key. Here are some tips to keep your engine running smoothly:

- Regularly check and maintain proper coolant levels to prevent overheating.

- Follow the manufacturer's recommended maintenance schedule for oil changes and other services.

- Inspect belts and hoses for signs of wear and replace them as needed.

- Monitor engine performance and address any unusual noises or vibrations promptly.

By staying proactive with maintenance, you can extend the life of your engine and avoid costly repairs.

Frequently Asked Questions

Here are some common questions related to engine head rectification:

- How long does the rectification process take? The process can take anywhere from a few hours to several days, depending on the extent of the damage and the complexity of the repair.

- Can I drive my car with a damaged engine head? It is not advisable to drive a vehicle with a damaged engine head, as it can lead to further damage and more costly repairs.

- Is it worth repairing an engine head? In most cases, repairing an engine head is a worthwhile investment, especially if the vehicle is relatively new or has sentimental value.

Conclusion

In conclusion, engine head rectification is a vital process for maintaining the performance and longevity of your vehicle's engine. By understanding the factors that influence the cost and taking proactive steps to prevent future issues, you can ensure your vehicle remains in top condition. Remember to choose a reputable repair facility with skilled technicians to guarantee a high-quality repair.

We encourage you to share your thoughts and experiences in the comments section below. Additionally, feel free to explore other articles on our site for more valuable insights into automotive maintenance and repair. Your feedback and engagement help us provide even better content in the future!

Data sources: Auto Service, Engineering Organization, Mechanic World.